Download PDF Brochures:

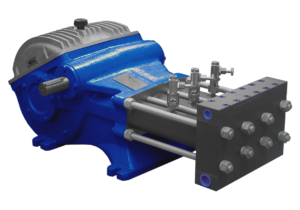

Features

- Pressure to 30,000 psi*

- Durable and Compact

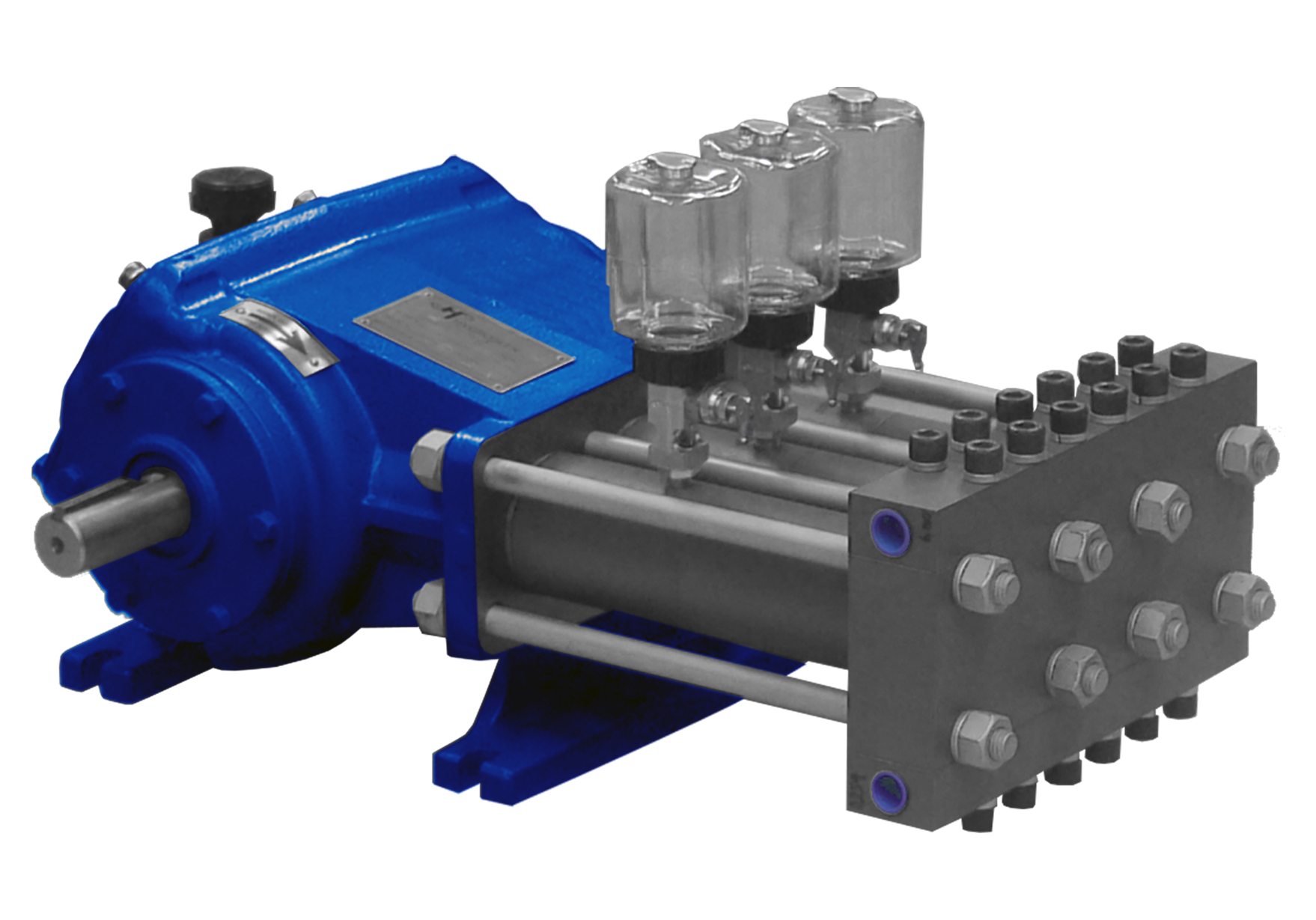

- Splash or Pressurized Lubrication Systems

- Easy Field Maintenance

- High Output Efficiency

- Corrosion Resistant Hardware

Applications

- Methanol Injection (special models available)

- Hydrostatic Testing

- Chemical Injection

- Downhole Equalization

- Flushing

- HPU Charging

- Hydroforming

Additional Info

- Maximum Continuous Power 35 hp

- Maximum Intermittent Power 40 hp

- Maximum Continuous Input 400 rpm

- Maximum Continuous Intermittent Input 450 rpm

- 1.75″ Stroke Length

- Available with 4-bolt SAE “C” female splined shaft for direct coupling of hydraulic motors

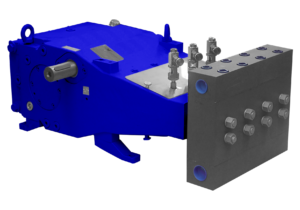

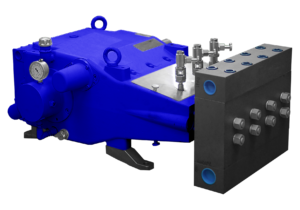

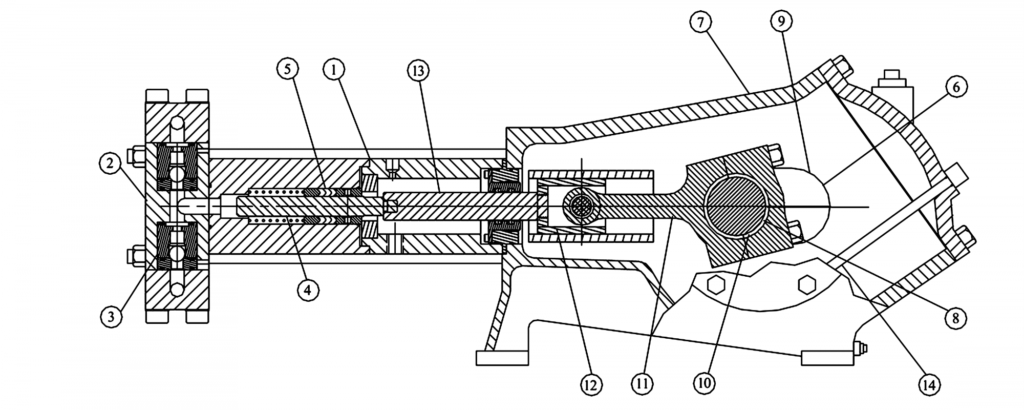

Fluid End

- Split Cylinder: The packing cylinder can be readily removed, thus giving easy accessibility to all replacement wear parts. Packing and plunger changes require minimal down time.

- Fluid Cylinder Body: Machined from high quality solid block alloy or stainless steel, ground to precision for maximum pump performance.

- Discharge and Suction Valve Assemblies: Each valve assembly is interchangeable and made from precision machine ground, hardened 17-4 PH stainless steel. No wing guide or threads are required, reducing field maintenance and increasing pump efficiency. The Hydroplex ball valve is rated to 30,000 psi and features a reversible double seat in hardened stainless steel. Balls are highly polished, ground and hardened stainless steel. All o-ring seals are flat surface designed, which reduces o-ring cutting and provides maximum pressure sealing.

- Power Plungers: The power plunger is heat-treated stainless steel ground and polished to an 8 rms surface finish for extended packing life.

- Plunger Packing: Multiple element Chevron style packing is used and is self adjusting, requiring minimal field maintenance. Packing lubrication is achieved with gravity oil drip or grease injection.

Power Body

- Pump Drive: Quiet running internal drive train cut and machined from high strength alloy steel. Assembled with conical tapered roller bearings.

- Crankcase: Oilfield rugged cast iron case protects internal components and the upper half of the case is easily removed for inspection and service.

- Automotive Type Crankshaft: Forged from alloy steel and balanced for continuous duty operations.

- Shaft Bearings: Precision conical tapered roller bearings support each shaft end.

- Crankshaft Journal Bearings: Journal bearings are high quality automotive type steel-backed inserts.

- Connecting Links: Links are cast iron with replaceable wrist-pin bushings.

- Crossheads: Heavy duty ductile iron crossheads eliminate side loads on power plungers.

- Pony Rods: Rods are smoothly ground and highly polished stainless steel, threaded and pinned to align perfectly with the crosshead and power plunger.

- Continuous Splash Lubrication: Oil in the crankcase reservoir is picked up by the crankshaft and spread to all moving parts.*

*Optional auxiliary lube available for low speed operation.